Kyocera introduces new innovative tooling solutions

Minimal deviation, a longer tool life and advanced machining efficiency – Kyocera’s EZ Bar Series is perfect for small manufacturing and it is constantly expanding to offer a wide variety of applications.

- Industrial Tools

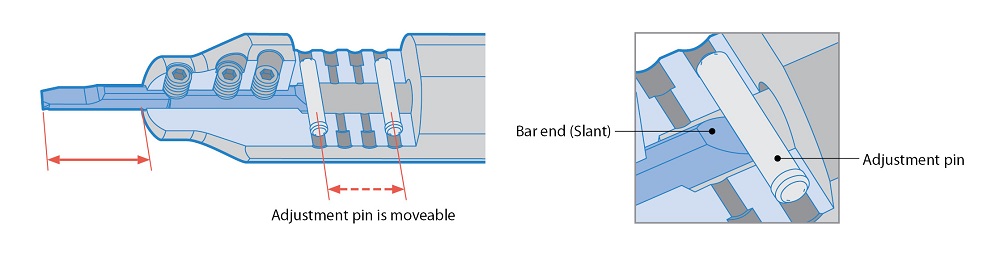

Kyoto/London - The manufacturing and internal machining of small parts requires precise quality tools – such as Kyocera’s EZ Bar Series, which has just been expanded with a new item: The EZBF type is able to make a one-shot boring process making a 90-degree step, which makes it a perfect addition to the innovative series. The whole EZ Bar series is ideal for high quality products due to their minimal deviation, the longer tool life and advanced machining efficiency compared to conventional tools. Especially with its unique EZ adjust function high precision indexing is easier than ever before: A wide variety of ID processes is possible – boring, back turning, grooving, facing and even threading – by just changing one tool. The latest addition to the line-up even allows for hole bottom face finishing processes.

1. Boring

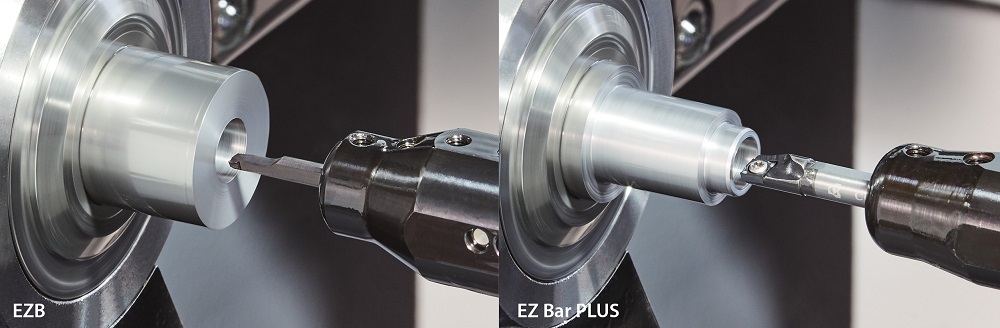

For great boring and back turning results chip breaker, neck length and grade can be selected for the individual purpose – even PCD and cBN are available. Also suitable for boring is the EZ Bar Plus, a reversible boring bar that offers a unique solution to minimise tooling costs. This indexable bar can perform boring processes with a minimum cutting diameter of 5 mm.

Face grooving and internal grooving processes can be performed by the EZ Bar as well. It supports minimum bore diameters of ⌀ 3-8 mm and cutting widths of 0.5-2.0 mm. With its high rake angle, the EZ Bar is designed for stable machining without vibration and shows good chip evacuation.

3. Facing

For facing applications, the EZ Bar Series has the EZVB type in the lineup. While up facing is not recommended, the EZVB type can be expanded to be able to perform hole bottom face finishing processes.

4. Threading

The EZ Bar Series is also able to perform threading processes. There is a wide range of applicable thread types in small ID processes: Metric, Unified, NPT, Whitworth, Parallel/Tapered pipe. The EZT type for threading has a bore diameter of ⌀ 3mm and is available for threading M4 metric screw threads.

For an even better high-quality finish the EZ Bar can be combined with the new PR1725 grade which is a PVD coated carbide grade. This original development of Kyocera named MEGACOAT NANO PLUS tackles several customer challenges at once: Producing a better surface finish, providing a cost-effective solution with a long tool life and integrating tools for steel and stainless steels. With its superior wear and adhesion resistance it also results in reduced cracking while machining.

To give customers more and better machining possibilities the EZ Bar lineup is constantly expanding. EZ Bar 45° Chamfering and EZ Bar Copying type are in the pipeline and will be released in early summer 2021 for a wider variety of applications.